Fiber lasers are popular for engraving metals, as they can engrave much more accurately than generic CO2 Lasers.

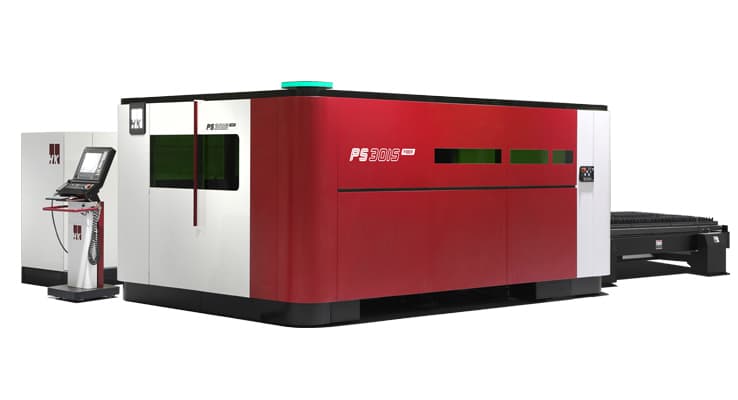

It can be used for flatbed cutting and bevel cutting, and the edges are neat and smooth. It is suitable for precision cutting of sheet metals. In addition, the robotic arm can do 3D cutting instead of the 5 axis laser cutter. Compared with CO2 laser cutters, fiber laser cutters will save space and gas consumption, and has a high photoelectric conversion rate. It is a new power tool of energy saving and environmental protection, and it is also one of the world's leading technological CNC machine tools. 1. High accuracy: The laser positioning accuracy is 0.05mm, and the repeated positioning accuracy is 0.03mm, 2. Narrow slit: The laser beam is focused into a small spot, so that the focus reaches a high power density, the material is rapidly heated to the point of vaporization, and the holes are vaporized. With the relative linear motion of the light beam and the material, the hole continuously forms a narrow slit, and the width of the slit is generally 0.10-0.20mm, 3. Smooth cutting edge: There is no burr on the cutting edge, and the roughness of the cutting surface is generally controlled within Ra6.5., 4. High speed: The cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than other metal cutting tools., 5. High quality: It is a non-contact cutting, which endures little thermal influence, the part basically has no thermal deformation, and completely avoids the slump formed when the material is punched and sheared., 6. Non-destructive cutting: The laser cutting head does not come into contact with the surface of the substrate, ensuring that the parts are not scratched., 7. Good flexibility: Laser has good flexibility to cut any graphics, including metal pipes and other shaped metals, 8. Save mold investment: Laser cutting requires no mold, no mold consumption, no mold repair, saving mold replacement time, thereby saving processing costs and reducing production costs, especially suitable for processing large projects, 9. Material saving: With CNC programming, the parts of different shapes can be cut to maximize the utilization rate of materials., 10. Easy to use: Using CAD software to design graphics, using CAM software to model and output laser cutting files, using CNC controller to drive the machine to achieve automatic metal cutting, 11. Safety and environmental protection: Less waste, low noise, clean, safe and pollution-free, greatly improving the working environment.